Kushandiswa Kwakakwana kweWaste Heat Drying System

Kushandiswa Kwakakwana kweWaste Heat Drying System

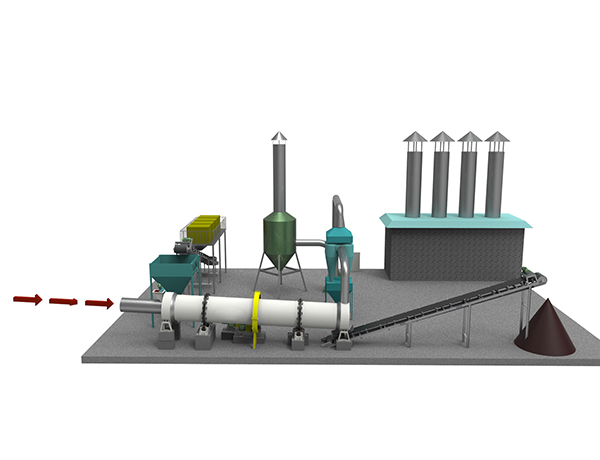

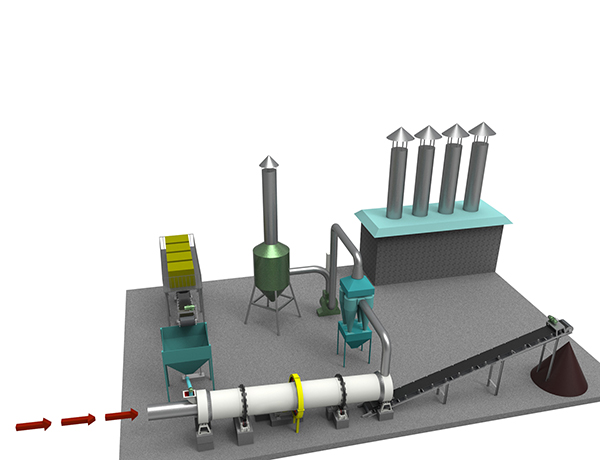

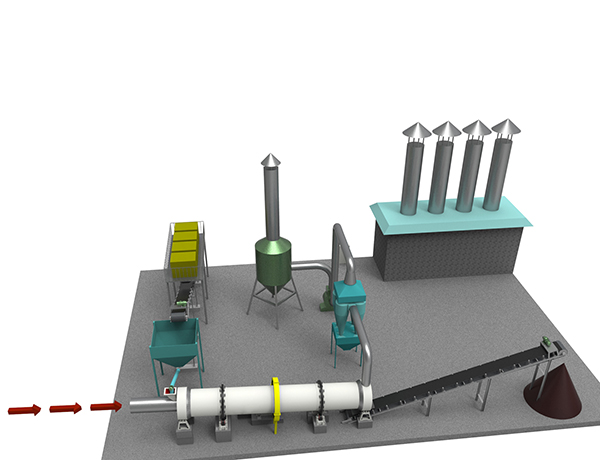

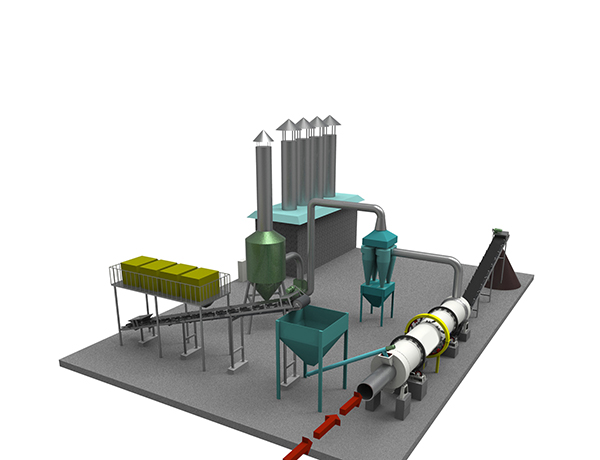

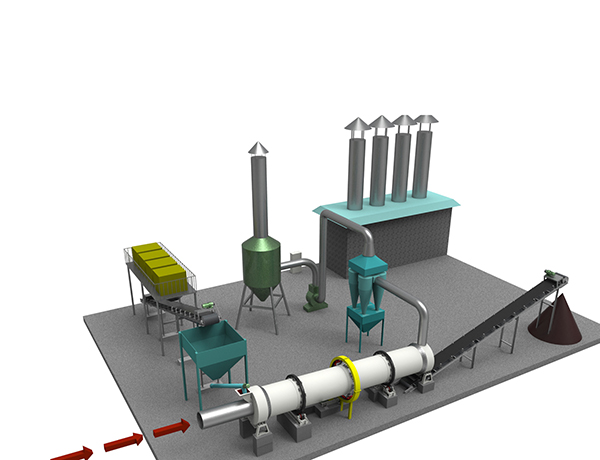

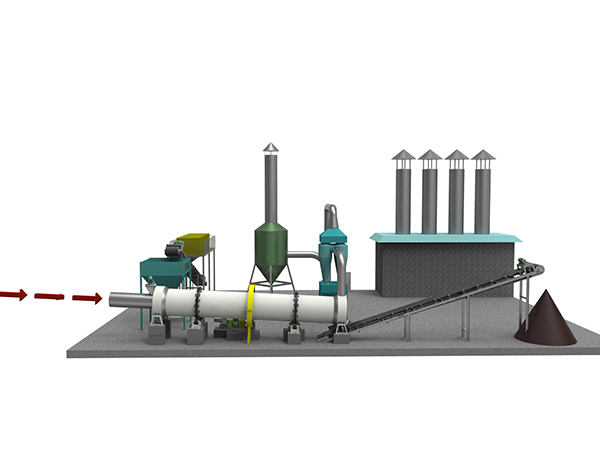

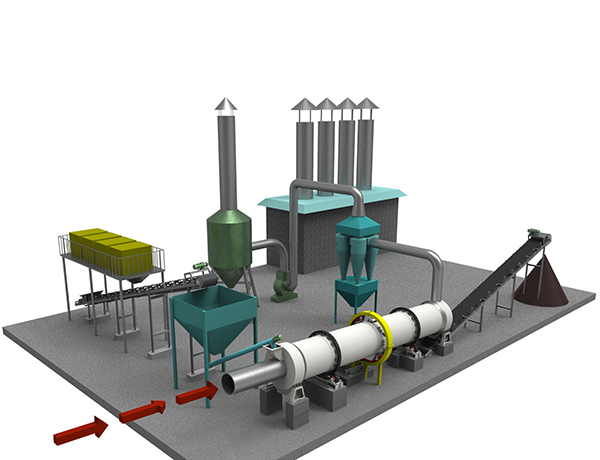

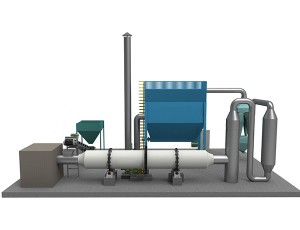

Process Flow

Iyo hurongwa hwekuwedzera mashandisirwo emagetsi emagetsi emagetsi anogona kugadzirwa maererano nemhando dzakasiyana, kutambisa kupisa kupisa uye kutambisa kupisa kuyerera.

Nyaya 1: 200T/D Sludge Processing Project yeimwe yeDalian Petrochemical Companies, uye kubuda kwemhepo: 750000 Nm³/h;tembiricha yekubuda: 135 ℃;Dhizaini yedu ndeye kushandisa matatu matatu eVS 4 x 32m dryer, ayo akaiswa mukugadzirwa.

Case 2: 4T/D Sludge Processing Project yeimwe yeShanghai mafekitori ekudhaya, exhaust flow: 10000Nm³/h, exhaust tembiricha:180℃;Dhizaini yedu ndeye kushandisa VS 2 x 5m intermittent dryer, iyo yakaiswa mukugadzirwa.

System Advantages

1. Kurasa kupisa kushandiswa, kuchengetedza simba uye kuchengetedza kwezvakatipoteredza;

2. Hapana kushandiswa kwemafuta, mashoma ekushandisa simba, iyo yekutanga guruva yekubvisa system inogona kushandiswa kuchengetedza mari;

3. Wana zvinhu zvakasvibirira munharaunda, imwe ivhu haidiwi;

4. High level of automation, basa rekuchengetedza;

5. Nguva yekuomesa inogona kugadziriswa, uye mvura yemvura inogona kudzorwa mushure mekuoma.

Technical Parameters

| Model | Silinda dhayamita(mm) | Hurefu hwesilinda(mm) | Silinda vhoriyamu(m3) | Silinda inotenderera kumhanya (r/min) | Simba (kW) | Huremu(t) |

| VS 0.6x5.8 | 600 | 5800 | 1.7 | 1-8 | 3 | 2.9 |

| VS 0.8x8 | 800 | 8000 | 4 | 1-8 | 4 | 3.5 |

| VS 1x10 | 1000 | 10000 | 7.9 | 1-8 | 5.5 | 6.8 |

| VS 1.2x5.8 | 1200 | 5800 | 6.8 | 1-6 | 5.5 | 6.7 |

| VS 1.2x8 | 1200 | 8000 | 9 | 1-6 | 5.5 | 8.5 |

| VS 1.2x10 | 1200 | 10000 | 11 | 1-6 | 7.5 | 10.7 |

| VS 1.2x11.8 | 1200 | 11800 | 13 | 1-6 | 7.5 | 12.3 |

| VS 1.5x8 | 1500 | 8000 | 14 | 1-5 | 11 | 14.8 |

| VS 1.5x10 | 1500 | 10000 | 17.7 | 1-5 | 11 | 16 |

| VS 1.5x11.8 | 1500 | 11800 | 21 | 1-5 | 15 | 17.5 |

| VS 1.5x15 | 1500 | 15000 | 26.5 | 1-5 | 15 | 19.2 |

| VS 1.8x10 | 1800 | 10000 | 25.5 | 1-5 | 15 | 18.1 |

| VS 1.8x11.8 | 1800 | 11800 | 30 | 1-5 | 18.5 | 20.7 |

| VS 1.8x15 | 1800 | 15000 | 38 | 1-5 | 18.5 | 26.3 |

| VS 1.8x18 | 1800 | 18000 | 45.8 | 1-5 | 22 | 31.2 |

| VS 2x11.8 | 2000 | 11800 | 37 | 1-4 | 18.5 | 28.2 |

| VS 2x15 | 2000 | 15000 | 47 | 1-4 | 22 | 33.2 |

| VS 2x18 | 2000 | 18000 | 56.5 | 1-4 | 22 | 39.7 |

| VS 2x20 | 2000 | 20000 | 62.8 | 1-4 | 22 | 44.9 |

| VS 2.2x11.8 | 2200 | 11800 | 44.8 | 1-4 | 22 | 30.5 |

| VS 2.2x15 | 2200 | 15000 | 53 | 1-4 | 30 | 36.2 |

| VS 2.2x18 | 2200 | 18000 | 68 | 1-4 | 30 | 43.3 |

| VS 2.2x20 | 2200 | 20000 | 76 | 1-4 | 30 | 48.8 |

| VS 2.4x15 | 2400 | 15000 | 68 | 1-4 | 30 | 43.7 |

| VS 2.4x18 | 2400 | 18000 | 81 | 1-4 | 37 | 53 |

| VS 2.4x20 | 2400 | 20000 | 91 | 1-4 | 37 | 60.5 |

| VS 2.4x23.6 | 2400 | 23600 | 109 | 1-4 | 45 | 69.8 |

| VS 2.8x18 | 2800 | 18000 | 111 | 1-3 | 45 | 62 |

| VS 2.8x20 | 2800 | 20000 | 123 | 1-3 | 55 | 65 |

| VS 2.8x23.6 | 2800 | 23600 | 148 | 1-3 | 55 | 70 |

| VS 2.8x28 | 2800 | 28000 | 172 | 1-3 | 75 | 75 |

| VS 3x20 | 3000 | 20000 | 14 | 1-3 | 55 | 75 |

| VS 3x23.6 | 3000 | 23600 | 170 | 1-3 | 75 | 85 |

| VS 3x28 | 3000 | 28000 | 198 | 1-3 | 90 | 91 |

| VS 3.2x23.6 | 3200 | 23600 | 193 | 1-3 | 90 | 112 |

| VS 3.2x32 | 3200 | 32000 | 257 | 1-3 | 110 | 129 |

| VS 3.6x36 | 3600 | 36000 | 366 | 1-3 | 132 | 164 |

| VS 3.8x36 | 3800 | 36000 | 408 | 1-3 | 160 | 187 |

| VS 4x36 | 4000 | 36000 | 452 | 1-3 | 160 | 195 |